Applications of Metal Welding Machines Today

Metal welding machines play a crucial role in many industrial sectors today. Beyond being tools for connecting metals, welding machines contribute significantly to the creation and maintenance of various products and structures. Let's delve deeper into the applications of metal welding machines.

.jpg)

Principles of Metal Welding Machines

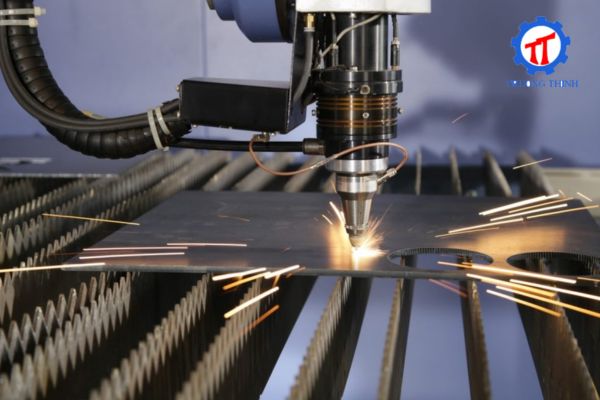

The operating principle of a laser welding machine involves generating and controlling laser light. During operation, the light source creates laser beams, amplifies them, and combines them with low-divergence. The process unfolds as follows:

-

Laser light generation: Laser light is created using a laser source and a polarizing lens to focus light into a small area, producing highly concentrated and energetic light.

-

Controlled laser light: The laser light is then manipulated using optical devices and computers to create precise welding patterns on the metal material.

-

Heating and welding: When the laser light hits the material, it generates high temperatures at the welding point, melting the material and forming a weld.

-

Laser control software: The laser light is controlled by software to create a sequence of welding points, forming a complete welding pattern on the metal surface.

.jpg)

Industries Where Metal Welding Machines Are Applied

Metal welding machines, especially laser welding machines, find widespread applications in various industries, including:

Automotive Manufacturing

-

Used for the rapid and precise welding of metal components in automobile production, including exhaust pipes, engine parts, and chassis.

-

Laser welding minimizes production time compared to traditional welding methods.

Medical Sector

-

Employed in the production of medical devices such as bed frames, pacemakers, infusion pumps, AEDs, and surgical instruments.

-

Laser welding technology ensures high precision, small welds, and no contamination, creating high-quality, safe, and aesthetically pleasing medical products.

Mechanical Fabrication

-

Widely used in the manufacturing of machinery, industrial cabinets, oil and gas equipment, and household appliances.

-

The advantages of laser welding, such as small and bright welds, make it ideal for crafting machinery and equipment from stainless steel, producing products with high aesthetic appeal.

Link: Understanding Metal Bending Machines

.jpg)

Considerations When Using Metal Welding Machines

To use metal welding machines safely and effectively, consider the following:

-

Check the coolant level regularly to prevent machine overheating.

-

Adjust the exhaust time before and after welding to protect the lens.

-

Regularly inspect the protective lens and avoid manual wiping.

-

Choose the appropriate welding nozzle for thickness and material.

-

Check the wire feeding system to ensure compatibility with wire diameter, ensuring safety and welding quality.

Conclusion

Metal welding machines play a vital role in various industries, from construction to metal manufacturing and energy. Understanding the working principles, application areas, and usage considerations helps maximize machine efficiency while ensuring safety for workers and the working environment.

-

Hotline: Mr. Hưng: 0936.988.978 - Mr. Tâm: 0904488455 - 0225.627.79.97

-

Production Workshop Address: Khu C, số 57 km5, Lâm Sản, P.Sở Dầu Q. Hồng Bàng

-

Website: Cơ Khí Trường Thịnh