Current Mechanical Machining Pricing – A Detailed Overview

Mechanical machining pricing is one of the top concerns for businesses when selecting a manufacturing partner. Machining prices not only reflect production costs but also demonstrate the technical capability, technology level, and professionalism of the service provider. Understanding how pricing is formed enables businesses to better control budgets, optimize investment efficiency, and ensure consistent product quality.

.jpg)

How Much Is Mechanical Machining Pricing?

Mechanical machining pricing is a common question among companies seeking reliable manufacturing partners. In reality, there is no fixed price applicable to all products, as pricing depends on multiple factors such as technical drawings, part complexity, tolerances, material selection, and production quantity.

Typically, mechanical machining pricing may be calculated based on machine hours, per individual part, or as a lump-sum quotation for each project. Single-piece machining, high-precision components, or difficult-to-machine materials often result in higher costs compared to mass production orders. Therefore, to receive an accurate quotation, businesses should provide complete and detailed technical requirements from the beginning.

Detailed Mechanical Machining Process

.jpg)

A well-defined process helps control quality, optimize costs, and ensure that mechanical machining pricing remains transparent and reasonable.

Receiving Technical Drawings and Requirements

The machining provider reviews technical drawings, dimensional specifications, tolerances, materials, surface treatments, and production quantities. This information forms the basis for selecting the machining approach and determining appropriate mechanical machining pricing.

Technical Consultation and Quotation

Based on the drawings, engineers recommend optimal machining solutions and suitable technologies such as CNC turning, CNC milling, laser cutting, or bending. A detailed and transparent quotation is then provided, outlining all cost components clearly.

Programming and Production Preparation

Once the quotation is approved, CNC programming is completed, materials are prepared, and fixtures and measuring tools are set up. This stage directly impacts machining accuracy and production timelines.

Machining and Quality Control

Machining is carried out strictly according to technical procedures. Products are inspected for dimensions, tolerances, and surface quality to ensure compliance before moving to the next stage.

Finishing and Delivery

After machining, products are cleaned, surface-treated if required, carefully packaged, and delivered on schedule—ensuring quality consistency and customer satisfaction.

See more:

http://cokhiphutrotruongthinh.com/thue-gia-cong-co-khi-o-dau-dia-diem-uy-tin-chat-luong-bv.html

Truong Thinh Mechanical Company – Transparent and Competitive Machining Pricing

.jpg)

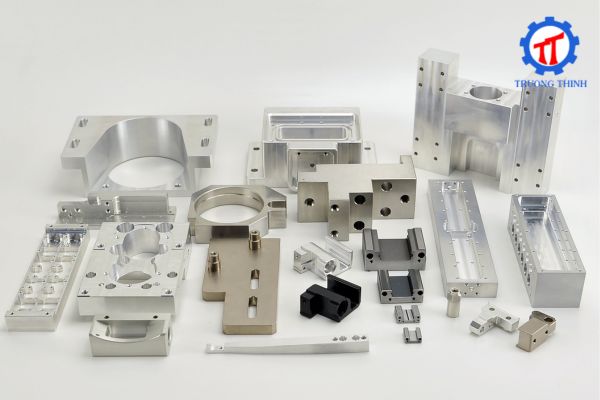

Mechanical machining pricing at Truong Thinh Mechanical is established based on transparency and alignment with each project’s technical requirements and quality standards. With many years of experience in mechanical fabrication, the company is equipped with modern machinery and a highly skilled team of engineers and technicians.

Truong Thinh Mechanical provides machining services for machine parts, jigs and fixtures, sheet metal, mechanical structures, and custom-made products. A clear workflow and strict quality control system ensure reliable delivery schedules, high precision, and long-term cost efficiency for clients.

Conclusion

Mechanical machining pricing depends on various technical factors and specific production processes. Choosing a machining partner with a professional workflow, clear quotations, and strong technical capabilities helps businesses optimize costs while maintaining high product quality. Truong Thinh Mechanical is a trusted partner for companies seeking efficient, precise, and sustainable mechanical machining solutions.

Truong Thinh Mechanical – Contact Information

Hotline:

Mr. Hung: 0936 988 978

Mrs. Tam: 0904 488 455

Tel: 0225 627 79 97

Factory Address: Zone C, No. 57, Km5 Lam San, So Dau Ward, Hong Bang District, Hai Phong, Vietnam

Website: http://cokhiphutrotruongthinh.com