What Is Custom CNC Machining? Machining Methods Explained

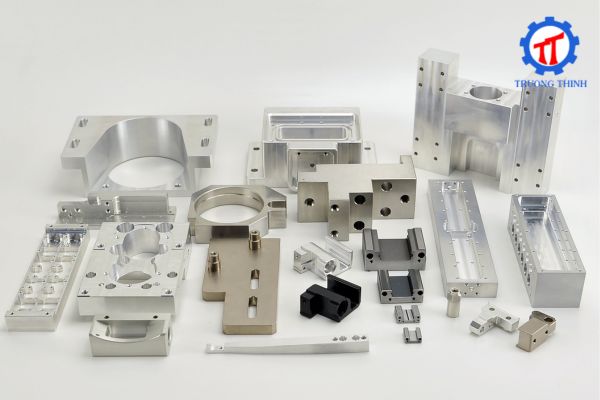

Custom CNC machining is an optimal solution for businesses that require the production of shafts, round parts, threaded components, and precision mechanical parts with consistent quality. By applying modern CNC technology, the machining process is fully automated, ensuring high accuracy, fast production speed, and flexible capability from single-piece machining to mass production. Truong Thinh Mechanical is proud to be a pioneering provider of professional CNC turning services in Vietnam.

.jpg)

What Is Custom CNC Turning?

Custom CNC machining is a mechanical manufacturing method that uses CNC lathes controlled by computer systems to produce rotational parts with high precision. Through CAD/CAM programming, cutting tools are automatically guided along predefined toolpaths to perform operations such as external turning, threading, drilling, boring, and grooving with exceptional accuracy and stability.

This method minimizes human error, improves product consistency, and optimizes production efficiency, making it especially suitable for industries requiring tight tolerances.

Key Features of CNC Turning Machining

.jpg)

Custom CNC machining offers significant advantages compared to traditional machining methods.

High precision is the most outstanding feature, with tolerances reaching up to ±0.005 mm and excellent surface finish quality. Thanks to a high level of automation, machining speed is greatly increased, reducing production time and overall costs.

In addition, CNC turning provides high flexibility, allowing the machining of complex geometries on a wide range of materials, from metals to engineering plastics, suitable for both prototype manufacturing and large-scale production.

CNC Turning Machining Methods

Custom CNC machining includes various basic machining techniques to meet diverse technical requirements.

-

OD and ID Turning: Machining external and internal cylindrical surfaces to achieve precise diameters.

-

Thread Cutting: Machining internal and external threads with accurate pitch and uniformity.

-

Grooving: Creating technical grooves according to engineering drawings.

-

Drilling and Boring: Drilling holes and finishing them to achieve high dimensional accuracy.

These methods can be flexibly combined in a single process to deliver complete products that fully meet customer specifications.

Read more: http://cokhiphutrotruongthinh.com/don-vi-nhan-gia-cong-co-khi-hai-phong-gia-re-uy-tin-bv.html

What Materials Are Used in Custom CNC Machining?

For metals, commonly used materials include carbon steel, alloy steel, and tool steel for industrial structures and machine components. Stainless steel grades 304 and 316 are widely applied in medical and food-processing industries due to their excellent corrosion resistance. Aluminum, copper, and brass are also frequently used for components requiring lightweight properties or high electrical conductivity.

In addition, CNC turning is also suitable for engineering plastics such as POM, Teflon, and PE, commonly used in mold manufacturing and mechanical components.

Trusted CNC Machining Address – Truong Thinh Mechanical

.jpg)

Custom CNC machining at Intech is carried out using modern CNC turning machines capable of handling complex technical drawings. A highly skilled and experienced team of engineers and technicians ensures flexible problem-solving and superior machining quality.

Intech applies the ISO 9001:2015 quality management system, strictly controlling every stage from programming and machining to inspection. Quotation response time is within 1 hour, production lead time is fast, and standard orders can be delivered within 3 days, ensuring optimal cost efficiency and operational effectiveness for customers.

Conclusion

Custom CNC machining is an indispensable solution in modern precision engineering, enabling the production of high-quality, consistent parts with exact tolerances. Choosing a reputable partner like Intech helps businesses optimize costs, ensure delivery schedules, and enhance manufacturing efficiency. With advanced technology, professional processes, and strong quality commitment, Intech is a reliable partner for all CNC turning needs.

Truong Thinh Mechanical Information

Hotline:

Mr. Hung: 0936 988 978

Mrs. Tam: 0904 488 455

0225 627 79 97

Factory Address: Zone C, No. 57, Km5, Lam San, So Dau Ward, Hong Bang District, Hai Phong, Vietnam

Website: http://cokhiphutrotruongthinh.com