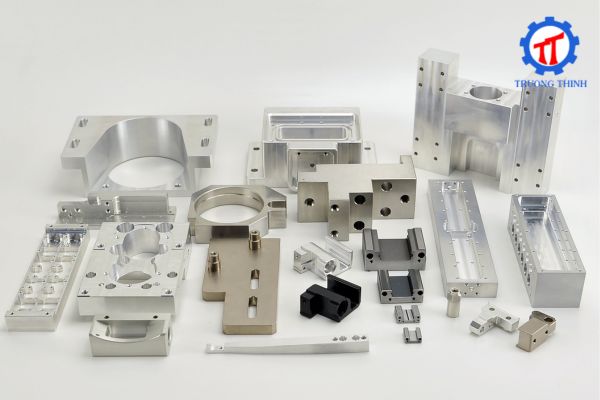

What is mechanical parts machining? Where to find a quality machining provider

Mechanical parts machining plays a key role in modern industrial manufacturing, especially with the strong development of CNC technology. Thanks to its ability to produce parts with high precision, excellent surface finish, and stable repeatability, this method helps businesses optimize costs, shorten production time, and improve product quality across many different industries.

(1).jpg)

What is mechanical parts machining?

Mechanical parts machining is the process of using mechanical machining methods to remove excess material from a workpiece to create a finished part according to technical drawings. Today, this activity mainly applies CNC (Computer Numerical Control) technology, which allows machines to be automatically controlled by computers, minimizing human errors.

Between the general concept and specific methods, understanding each machining technique helps businesses choose the most suitable solution for their production requirements.

Common CNC machining methods

.jpg)

Mechanical parts machining using CNC today mainly focuses on two methods: CNC milling and CNC turning, each suitable for different types of parts.

CNC Milling

-

Uses rotating cutting tools to remove material

-

Suitable for machining flat surfaces, curved surfaces, and complex shapes

-

Widely applied in mold making, jigs, fixtures, and machine components

CNC Turning

-

Machining by rotating the workpiece around a fixed axis

-

Mainly used for cylindrical parts such as shafts, tubes, and bushings

-

Ensures high concentricity and precision

Outstanding features of mechanical parts machining

Mechanical parts machining not only meets strict technical requirements but also brings many outstanding benefits to manufacturing businesses.

Before going into each advantage, it is clear that CNC technology has completely changed the approach in the field of precision mechanical engineering.

High precision and repeatability

CNC mechanical parts machining can achieve tolerances at the micron level, ensuring that parts have uniform and extremely accurate dimensions. This is especially important for components used in machinery systems or automated production lines.

Material flexibility

Mechanical machining can be applied to a wide range of materials such as steel, stainless steel, aluminum, copper, engineering plastics, and composite materials. Thanks to this flexibility, businesses can easily meet the diverse requirements of different industries.

Suitable for both single-piece and mass production

CNC mechanical parts machining is particularly effective for low- to medium-volume production (under 1,000 parts). Programming is done only once, but parts can be produced repeatedly with consistent quality.

Standard mechanical machining process

.jpg)

Mechanical parts machining is carried out according to a strict process to ensure that the final products meet the highest technical and quality requirements.

Before a product is completed, each stage plays an important role and is closely connected to the others. The steps in a standard CNC machining process include:

-

CAD design: The part is accurately modeled using design software

-

CAM programming: Converting the drawing into a CNC machine control program

-

Machine and material setup: Fixing the workpiece and setting appropriate cutting parameters

-

Machining: Performing milling, turning, drilling, tapping, and cutting according to the program

-

Quality inspection: Measuring dimensions, tolerances, and surface quality

Truong Thinh Mechanical – A trusted machining provider

Truong Thinh Mechanical is a high-quality mechanical machining provider trusted by many businesses for years. With a sustainable development orientation, Truong Thinh continuously invests in modern CNC machinery systems to meet requirements for precision mechanical parts machining, jigs, fixtures, and products based on technical drawings.

The team of experienced engineers and technicians works professionally and always focuses on quality control at every stage. Thanks to a closed production process, competitive pricing, and reliable delivery schedules, the company has become a trusted partner for many customers in and beyond the industrial sector.

Conclusion

Mechanical parts machining is an indispensable solution in modern industrial manufacturing, helping to create precise, durable, and consistent components. With the support of CNC technology, businesses can optimize costs, increase design flexibility, and improve production efficiency. Choosing the right professional machining partner is the key factor in ensuring quality and long-term sustainable development.

Truong Thinh Mechanical Information:

Hotline: Mr. Hung: +84 936 988 978 – Mrs. Tam: +84 904 488 455 – +84 225 627 7997

Factory address: Zone C, No. 57, Km5, Lam San, So Dau Ward, Hong Bang District, Hai Phong, Vietnam

Website: http://cokhiphutrotruongthinh.com