Where to Find Stainless Steel Mechanical Machining in Hanoi? Detailed Quotation

Stainless steel mechanical machining in Hanoi is increasingly chosen by businesses, factories, and individuals thanks to its ability to meet strict technical requirements, high durability, and wide applicability. With the development of CNC technology, stainless steel products not only achieve near-absolute precision but also help optimize costs, shorten production time, and improve long-term operational efficiency.

.jpg)

What Is Stainless Steel Mechanical Machining in Hanoi?

Stainless steel mechanical machining in Hanoi is the process of using modern mechanical methods to process stainless steel materials in order to create machine parts, components, or finished products according to technical requirements.

This process commonly applies CNC technologies such as CNC milling, CNC turning, wire-cut CNC, and EDM machining, enabling precise processing of complex parts with extremely tight tolerances. As a result, stainless steel products achieve high uniformity, smooth surface finishes, and meet strict technical standards across various industrial sectors.

Common Stainless Steel Types Used in Mechanical Machining

.jpg)

Inox 304 – Corrosion Resistance, Food Safety

Stainless steel mechanical machining in Hanoi frequently uses Inox 304, composed of approximately 18% chromium and 10% nickel. This non-magnetic stainless steel offers excellent corrosion resistance, making it suitable for food processing, medical applications, and humid environments. Although its cost is higher, Inox 304 provides superior durability and safety.

Inox 201 – Cost-Effective, Stable Durability

Inox 201 contains about 18% chromium and 8% nickel, is non-magnetic, and offers fairly good durability at a reasonable price. However, it should be protected from direct contact with acids or salts to ensure product longevity.

Inox 430 – Low Cost, General Applications

Inox 430 contains approximately 18% chromium and no nickel. This type is magnetic and has lower corrosion resistance, making it more susceptible to surface oxidation in harsh environments. Its main advantage is low cost, suitable for products with lower surface durability requirements.

Outstanding Advantages of CNC Stainless Steel Machining

.jpg)

High Precision and Aesthetic Quality

Stainless steel mechanical machining in Hanoi using CNC machines achieves near-perfect accuracy, with tolerances as low as 0.001mm. As a result, stainless steel machine parts feature smooth surfaces, consistent dimensions, and high aesthetic value.

High Productivity and Cost Optimization

CNC machines operate automatically with high capacity, allowing mass production in a short time. Programming is required only once, saving setup time, reducing material waste, and optimizing production costs.

Flexibility in Design and Materials

CNC machining allows quick program adjustments to suit different product designs. This technology can process various stainless steel grades such as 304, 201, and 430, as well as other metal materials.

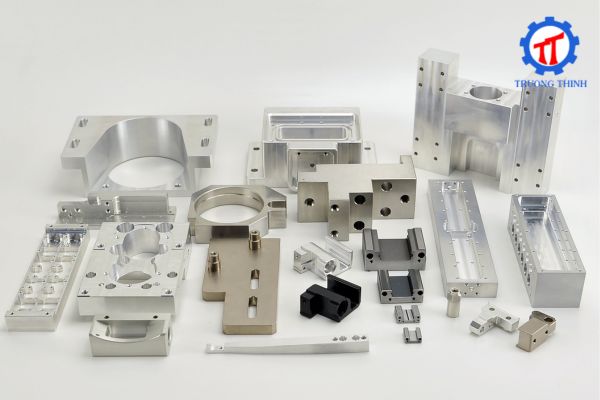

Popular Stainless Steel Mechanical Products in Hanoi

Stainless steel mechanical machining in Hanoi is widely applied across industrial production and daily life. Common products include:

-

Stainless steel machine parts and precision mechanical components

-

Stainless steel jigs and fixtures for assembly and production

-

Industrial stainless steel worktables, racks, and frames

-

Machine housings and structural stainless steel components based on drawings

-

Stainless steel products for food processing, medical, and automation industries

Thanks to high durability and corrosion resistance, stainless steel products ensure long service life and stable performance.

Read more: http://cokhiphutrotruongthinh.com/don-vi-nhan-gia-cong-co-khi-uy-tin-gia-re-2026-bv.html

Truong Thinh Mechanical – A Trusted Stainless Steel Machining Company

Stainless steel mechanical machining in Hanoi at Truong Thinh Mechanical is a reliable choice for businesses seeking a professional manufacturing partner. With many years of experience in precision mechanical machining, Truong Thinh owns a modern CNC machinery system and a team of highly skilled engineers and technicians.

Truong Thinh Mechanical specializes in machining stainless steel machine parts, jigs, fixtures, sheet metal, and custom stainless steel products. All processes are carried out directly at the factory without intermediaries, ensuring strict quality control and optimized costs for customers.

In addition, the company provides technical consulting, design optimization, and suitable machining solutions to ensure products meet technical requirements and production schedules.

Conclusion

Stainless steel mechanical machining in Hanoi is an effective manufacturing solution that meets the increasingly high demands for precision, durability, and aesthetics in modern mechanical products. Choosing a reputable company like Truong Thinh Mechanical helps businesses optimize costs while ensuring long-term quality and on-time delivery.

Truong Thinh Mechanical Information:

Hotline:

Mr. Hung: +84 936 988 978

Mrs. Tam: +84 904 488 455

Tel: +84 225 627 79 97

Factory Address: Zone C, No. 57, Km5 Lam San, So Dau Ward, Hong Bang District, Hai Phong, Vietnam

Website: http://cokhiphutrotruongthinh.com