What is Metal Fabrication? Popular Fabrication Methods

Welding is a critical process in the industry and mechanical engineering, allowing the joining and combination of metal components to create various mechanical products and structures. In this article, we will delve deeper into the process of metal welding.

.jpg)

What Is Metal Welding?

Metal welding is an essential process in the industrial and mechanical engineering field. It involves connecting metal components by using heat or pressure, sometimes with the addition of filler material, depending on the type of welding applied. Choosing the appropriate welding method is crucial to ensure efficiency and quality in the metal welding process for each specific project.

Advantages of Metal Welding

The advantages of metal welding lie in its ability to create strong connections between metal components, ensuring stability and high load-bearing capacity. Metal welding also enables the creation of custom cuts, joints, or weld lines, enhancing flexibility and diversity in design. Additionally, metal welding helps:

-

Increase Durability: When welding is done correctly, it provides strength and load-bearing capacity to the product.

-

Ensure Aesthetics: Metal welding can create smooth and neat weld lines, ensuring aesthetic appeal.

-

Waterproofing and Heat Resistance: Metal welding creates a tight connection, making it waterproof and able to withstand high temperatures.

-

Design Flexibility: Metal welding allows for custom and diverse components, optimizing product design.

-

High Performance: Welding methods can be carried out quickly, saving time and increasing production efficiency.

.jpg)

Most Common Metal Welding Methods Today

Each welding type has its own advantages and specific applications, depending on the purpose and specific requirements of the welding process. Depending on the specific requirements, you can choose the appropriate welding method.

Gas Tungsten Arc Welding (TIG Welding)

-

Also known as TIG welding, this method uses an electric current to create a weld.

-

It is commonly used in construction, steel fabrication, pipelines, and heavy equipment repairs.

-

A weld is created by generating an electric current between the welding rod and the metal surface.

Gas Metal Arc Welding (MIG Welding)

-

It uses a continuous wire feed instead of self-melting welding rods.

-

A shielding gas, typically carbon dioxide or a carbon dioxide and argon mixture, ensures a safe welding environment and reduces smoke.

Flux-Cored Arc Welding (FCAW)

-

Combines the advantages of MIG welding with a hot-melting electrode inside the metal tube.

-

Preferred for its high electrode speed and efficiency.

Gas Tungsten Arc Welding (GTAW)

-

Uses an outer tungsten rod to generate the necessary heat for welding.

-

It produces strong, high-quality welds, with clean, visually appealing results.

.jpg)

Why Choose Cơ Khí Trường Thịnh for Metal Welding?

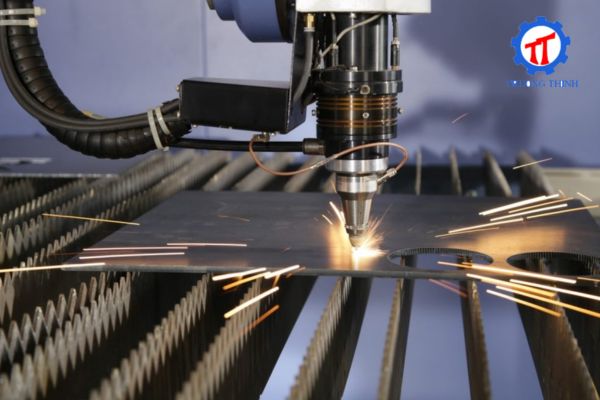

Cơ Khí Trường Thịnh is the top choice for metal welding because it offers several superior benefits. First and foremost, we have a team of professional and experienced welders, ensuring that every product is completed with the highest quality.

We provide a variety of different welding methods to suit all types of metals and specific requirements. Especially, we utilize modern equipment and advanced technology to ensure beautiful, high-quality, and durable welds. If you need reliable metal welding services, Cơ Khí Trường Thịnh is the right choice.

Conclusion

Metal welding is a crucial process in the industrial and manufacturing industry. It brings many important advantages, including hardness, precision, and material diversity. Cơ Khí Trường Thịnh is the ideal place to take advantage of the benefits of metal welding, with experience and modern equipment. Contact us for more details and get a quote for the best metal welding services.

Contact Information:

-

Hotline: Mr. Hưng: 0936.988.978 - Mr. Tâm: 0904488455 - 0225.627.79.97

-

Manufacturing Workshop Address: Khu C, số 57 km5, Lâm Sản, P.Sở Dầu Q. Hồng Bàng

-

Website: http://cokhiphutrotruongthinh.coma