Aluminum sheet laser cutting - Current popular aluminum laser cutting methods.

Aluminum sheet laser cutting is a widely used metal processing process in the industrial sector. The combination of laser technology and aluminum metal brings numerous advantages and high accuracy capabilities. Learn about this method in the following article.

.jpg)

What is Aluminum Sheet Laser Cutting?

Aluminum sheet laser cutting is the process of using a laser beam to cut aluminum metal sheets according to specific molds or designs. This method not only creates sharp cutting edges but also minimizes deformation and limits cracks.

.jpg)

Key Advantages of Aluminum Sheet Laser Processing

Aluminum sheet laser processing brings several outstanding advantages, especially in the metal industry. Firstly, this method ensures exceptional accuracy, allowing for cutting complex designs without the need for molds.

Importantly, aluminum sheet laser cutting reduces deformation and cracking significantly. Concentrating energy at a small point during the cutting process helps prevent bending and maintains the product's shape without alteration.

Products after cutting typically have a smooth surface, eliminating the need for additional finishing stages. This saves time and resources while producing high-quality products.

Common Aluminum Sheet Laser Cutting Methods

During the process of aluminum sheet metal processing, the use of aluminum sheet laser cutting technology has brought convenience and efficiency. Here are two popular aluminum sheet laser cutting methods:

.jpg)

CO2 Laser Cutting

This method utilizes CO2 gas to create a laser beam capable of cutting through aluminum metal. The CO2 laser beam is generated by passing electric current through CO2 gas, creating high-energy sources that contribute to forming the laser beam. This method is often used for cutting non-conductive materials like aluminum. It provides good cutting accuracy and speed.

Fiber Laser Cutting

This method employs fiber optics to create a laser beam. The fiber laser beam is generated by passing light through thin optical fibers. This method is suitable for cutting thin metal materials, creating sharp cutting lines. Fiber laser cutting ensures accurate and efficient cutting.

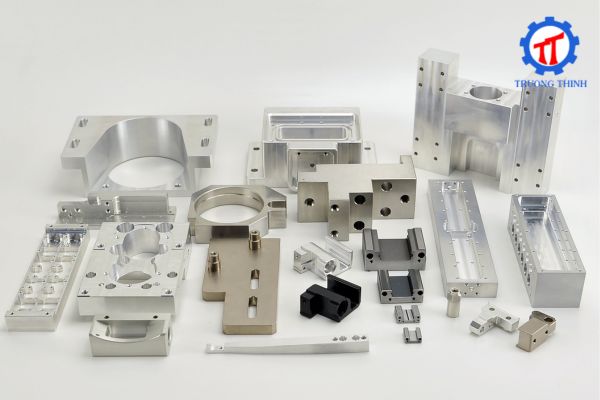

Aluminum Sheet Laser Cutting Service at Cơ Khí Trường Thịnh

Cơ Khí Trường Thịnh takes pride in being a leading entity in aluminum sheet laser cutting. We possess modern equipment and a professional technical team, committed to providing aluminum sheet laser cutting products with the highest accuracy and quality.

With both CO2 laser cutting and fiber laser cutting methods, we have the capability to process aluminum sheets of varying thicknesses and complexities. Customers can trust in the accuracy and finish of the products after the cutting process.

We pledge to offer optimized aluminum sheet laser cutting services, catering to diverse needs across different industries. With our reputation and experience, Cơ Khí Trường Thịnh is a reliable partner for quality laser cutting projects.

Conclusion

The aluminum sheet laser cutting method brings efficiency and high accuracy to metal processing. By utilizing CO2 laser cutting and fiber laser cutting methods, Cơ Khí Trường Thịnh meets the diverse and quality-oriented laser cutting needs of customers.

Hotline: Mr: Hưng: 0936.988.978 - Ms. Tâm: 0904488455 - 0225.627.79.97

Website: http://cokhiphutrotruongthinh.com