Trusted and Professional Iron Laser Cutting Service as per your requirements.

With the advancement of technology, receiving trusted and professional iron laser cutting services has become essential for businesses. The following article will provide you with a better understanding of the laser cutting process and the iron laser cutting services at Cơ Khí Trường Thịnh.

.jpg)

What is Iron Laser Cutting?

Iron laser cutting is a metal processing procedure that employs laser beam technology to create precise cutting lines on iron sheets. In this process, the laser beam focuses energy on a small point, heating and melting the iron material to create the desired cut lines.

The iron laser cutting method delivers high accuracy and the ability to cut complex shapes that traditional cutting methods struggle with. This optimization enhances the manufacturing process, producing high-quality metal products that meet the diverse demands of the industry.

.jpg)

What Sets Cơ Khí Trường Thịnh's Iron Laser Cutting Service Apart?

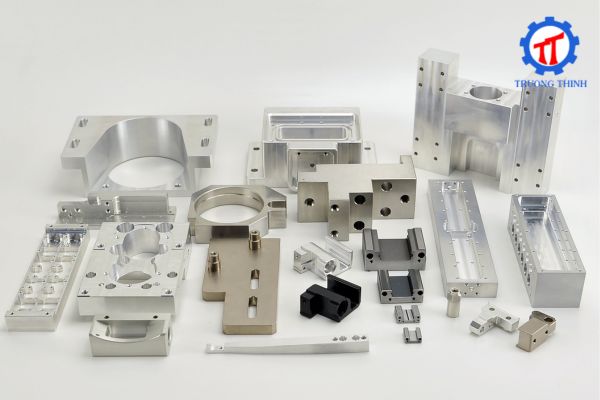

When you choose iron laser cutting services at Cơ Khí Trường Thịnh, you will experience notable advantages:

-

State-of-the-Art Laser Cutting Technology: We employ cutting-edge laser cutting technology, ensuring optimal accuracy and processing speed. A repeatability error of just ±0.025 mm ensures the highest precision in products.

-

Diverse Range: We offer laser cutting services for various materials such as copper, aluminum, stainless steel, and steel, with thicknesses up to 25 mm and large sizes of up to 2.5 x 6 meters, catering to a wide range of production needs.

-

Surface Treatment and Finishing: We not only provide laser cutting services but also offer surface treatment and product finishing according to customer requirements, ensuring perfect and ready-to-use products.

-

On-Time Delivery and Quality Assurance: We commit to maintaining schedules and ensuring quality, from small projects to large urban projects, providing customer satisfaction.

.jpg)

Cơ Khí Trường Thịnh's Iron Laser Cutting Process

Our iron laser cutting process adheres to technical requirements and ensures production schedules. We promise to deliver products of the highest quality and accuracy to all customers. The following are the specific steps involved in the laser cutting process for our customers:

Material Preparation

The process begins with preparing the materials to be cut. Customers provide design files or request our technical team to design as per their requirements.

Technical Specifications

Determine the type of iron material to be cut and the corresponding thickness. Our technical team will provide specific technical requirements to ensure an effective cutting process.

Configure Laser Cutting Machine Settings

Next, we configure the settings of the laser cutting machine. This includes setting the correct cutting parameters, adjusting cutting speed, laser power, and other settings to ensure the best accuracy and performance.

Laser Cutting Process

After the settings are completed, we proceed with the laser cutting process. This process is carried out by modern laser cutting machines, creating precise and smooth cutting lines as per the requested design.

Conclusion

Receiving trusted and professional iron laser cutting services is crucial in the metal production process. With a reputation and experience in the mechanical industry, Cơ Khí Trường Thịnh commits to providing iron laser cutting services with high quality and meeting every customer's needs.

Hotline: Mr: Hưng: 0936.988.978 - Ms. Tâm: 0904488455 - 0225.627.79.97

Website: http://cokhiphutrotruongthinh.com