Is powder coating or liquid coating better? Detailed comparison

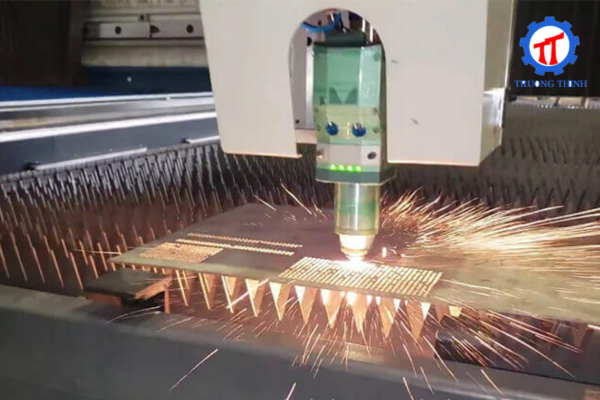

Powder coating is an advanced surface–finishing technology that uses positively charged solid paint particles to adhere firmly to negatively charged metal surfaces, creating a strong, even, and aesthetically pleasing coating. This technology is widely applied in mechanical engineering, furniture production, and industrial equipment manufacturing thanks to its excellent corrosion resistance, long-lasting color stability, and superior adhesion. The article below helps you understand the composition, working principles, and outstanding advantages of powder coating technology.

.jpg)

What is powder coating?

Powder coating is a modern and popular finishing technology in industrial production due to its high adhesion, superior aesthetics, and user safety. Unlike traditional solvent-based paints, powder coatings are electrically charged and bond to metal substrates through electrostatic attraction, forming a durable and uniform protective layer.

Powder coating is composed of polymer resins, pigments, and special additives. Because the coating exists in solid form, it contains no solvent and produces zero VOC emissions. This makes powder coating an environmentally friendly, non-toxic, and sustainable solution. As manufacturing standards become increasingly strict, especially in large-scale factories, this advantage becomes even more significant.

How does powder coating work?

.jpg)

Powder coating works based on the principle of electrostatic attraction. When the spray gun charges the powder particles with positive ions, they are strongly attracted to the negatively charged metal surface. This ensures that the coating adheres tightly and distributes evenly across the entire product—even parts with complex shapes.

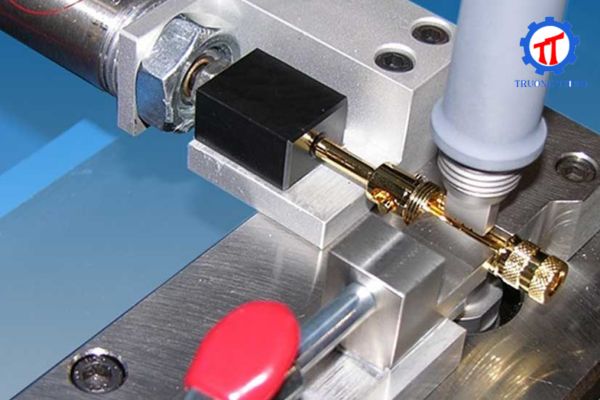

After spraying, the product is placed into a curing oven at 180–200°C, where the powder melts, flows, and chemically bonds to form a smooth, durable, finished coating.

This principle enables highly uniform coverage with minimal manual intervention, reducing risks of uneven color, streaks, or missing spots. As a result, powder-coated products consistently meet export-grade and mass-production quality standards.

Outstanding advantages of powder coating

Powder coating offers numerous advantages that many other finishing methods cannot match:

High durability and corrosion resistance

Cured powder forms a tough, protective layer that resists scratches, rust, and harsh weather conditions for many years.

Perfectly uniform color

Because adhesion depends on electrical charge, the coating spreads evenly on all surfaces—even with multiple layers or complex shapes. This is a significant advantage over liquid electrostatic coating.

No harmful solvent emissions

Liquid coatings contain VOCs that harm health and the environment. Powder coatings contain no VOCs, making them a cleaner and safer choice.

Cost-saving thanks to recyclability

Overspray powder can be collected and reused up to 98% via the booth’s filtration and recovery system. In contrast, liquid coatings cannot be reused.

Strong mechanical resistance

The finished coating has excellent strength, does not crack or peel, and maintains its color over time—ideal for products exposed to frequent mechanical impact.

More information:

http://cokhiphutrotruongthinh.com/don-vi-gia-cong-co-khi-chinh-xac-theo-yeu-cau-uy-tin-bv.html

Limitations of powder coating

.jpg)

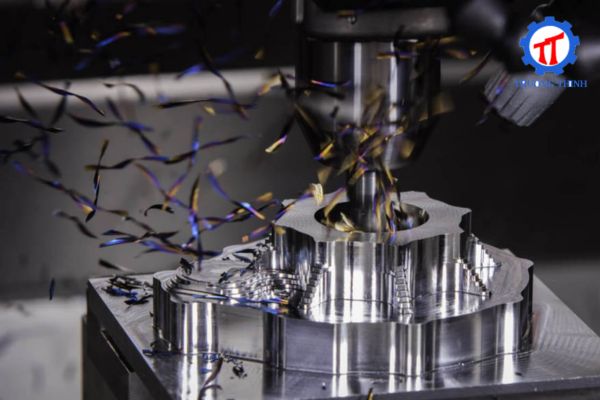

Although powder coating is highly efficient, it does have certain drawbacks:

-

High initial investment cost, requiring a spray booth, filtration system, and large curing oven.

-

Strict surface preparation requirements—dust or small particles can cause permanent defects.

-

Not suitable for heat-sensitive materials such as plastic, rubber, or natural wood.

-

Color cannot be altered after curing; incorrect color requires complete rework.

However, most limitations relate to setup and technique rather than the quality of the coating itself.

Conclusion

Powder coating is becoming an essential trend in modern industry thanks to its superior durability, consistency, and safety. Despite having higher initial investment and more complex technical requirements, the long-term benefits greatly outweigh those of traditional painting methods. With material savings, reduced emissions, and improved product quality, powder coating will continue to maintain its strong position in the market.

Thông tin Cơ Khí Trường Thịnh:

-

Hotline: Mr. Hưng: 0936.988.978 – Mrs. Tâm: 0904.488.455 – 0225.627.79.97

-

Factory address: Khu C, No. 57 km5, Lâm Sản, Sở Dầu Ward, Hồng Bàng District, Hải Phòng

-

Website: http://cokhiphutrotruongthinh.com