What is an ultrasonic metal welding machine? Advantages and disadvantages in detail

An ultrasonic metal welding machine is a device that uses high-frequency ultrasonic waves to create fast, clean, and extremely durable welds. This technology does not require welding rods, produces no slag, and does not deform the material, making it increasingly popular in the electronics, automotive, aerospace, and medical equipment industries.

.jpg)

What is an ultrasonic metal welding machine?

An ultrasonic metal welding machine uses high-frequency ultrasonic vibrations to generate localized heat at the contact point, allowing two metal materials to bond without heating the entire surface. This method operates by generating micro-friction between surfaces, causing partial melting and bonding under high pressure. Because it does not produce excessive heat, it is ideal for components requiring high precision and long-term durability.

Structure of an ultrasonic welding machine

Before diving deeper, it is essential to understand the machine’s main components.

Ultrasonic vibration generator

The machine uses a generator to create ultrasonic waves at frequencies between 20–40 kHz. These vibrations are amplified through a converter and transmitted to the welding horn.

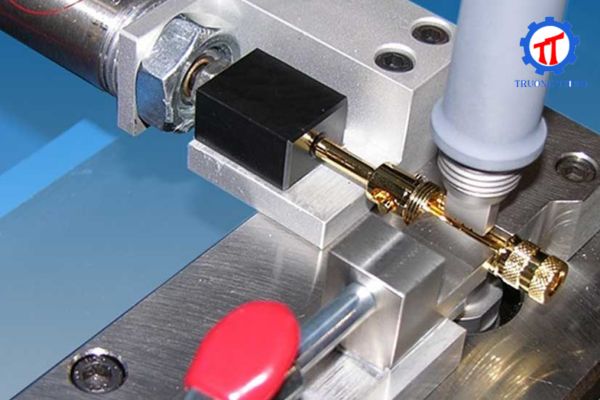

Welding horn (Horn)

The horn directly contacts the material, delivering force and vibration. It is typically made from titanium or specialized steel to withstand continuous oscillation.

Pressure control system and fixture

An ultrasonic metal welding machine includes a precise pressure-control mechanism to stabilize welding force and ensure consistent bonding quality.

Reference: http://cokhiphutrotruongthinh.com/ky-thuat-phun-son-tinh-dien-la-gi-quy-trinh-chuan-xac-nhat-bv.html

Operating principle of an ultrasonic metal welding machine

.jpg)

The machine functions using vibrational energy rather than conventional heat.

Generation of high-frequency vibration

The ultrasonic metal welding machine converts electrical energy into mechanical energy through a piezoelectric transducer, producing powerful ultrasonic vibrations.

Transmission of vibration to metal surfaces

Ultrasonic waves combined with pressure create internal friction, causing the metal surface to melt within milliseconds.

Bonding without damaging material structure

This method forms a durable joint without deforming or altering the surrounding metal structure.

Common types of ultrasonic metal welding machines

Each machine type is suited for different materials and technical requirements.

Spot ultrasonic welding machines

Used for bonding copper and aluminum wires or small components in electronics and battery manufacturing.

Long-seam ultrasonic welding machines

Designed for thin metal sheets, tubes, and panel-shaped components, creating long, continuous weld seams.

Rotary ultrasonic welding machines

Used for circular or cylindrical products such as metal filters, steel tubes, and components with rotational geometry.

Outstanding advantages of ultrasonic metal welding machines

.jpg)

Short introduction: This technology offers benefits far beyond traditional welding methods.

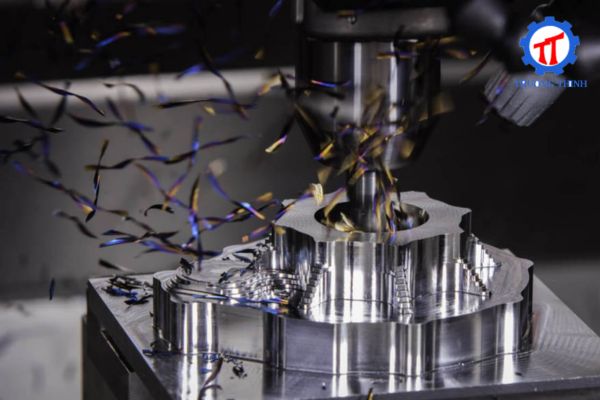

No high heat, no deformation

Ultrasonic metal welding generates heat only at the joint, preventing warping, burning, or surface damage.

No welding rods or filler materials

Bonding occurs naturally through pressure and vibration, reducing material costs.

Extremely fast welding speed

Each weld takes only 0.1–1 second, ideal for mass production.

Clean, strong, slag-free welds

An ultrasonic metal welding machine creates flawless joints, suitable for electronics and precise equipment components.

Disadvantages of ultrasonic metal welding machines

Despite its effectiveness, the technology has certain limitations.

High initial investment

Ultrasonic welding systems require advanced equipment and specialized welding horns.

Not suitable for large or very thick materials

Ultrasonic waves struggle to penetrate thick metal layers.

Requires precise surface preparation

To achieve optimal strength, both surfaces must be clean and flat.

Conclusion

Ultrasonic metal welding machines represent advanced welding technology that delivers exceptional speed, durable joints, and broad industrial applicability. With no high heat, no welding rods, and consistent weld quality, this method helps businesses enhance productivity and reduce manufacturing costs. As technology continues to advance, ultrasonic welding will remain a top choice for modern production.

Truong Thinh Mechanical Information:

-

Hotline:

Mr. Hung: 0936.988.978

Mrs. Tam: 0904.488.455 - 0225.627.79.97 -

Factory Address: Zone C, No. 57 km5, Lam San, So Dau Ward, Hong Bang District, Hai Phong

-

Website: http://cokhiphutrotruongthinh.com