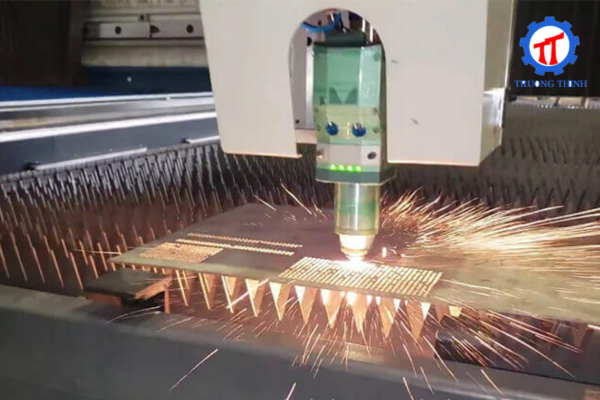

What Is Precision Machining? The Importance of Accuracy

What is precision machining and why does this technology play such an essential role in modern manufacturing? With the ability to create components with extremely high accuracy, precision machining has become the foundation of industries such as aerospace, automotive, medical devices, and electronics. This process applies CNC technology and advanced engineering methods to ensure outstanding quality, reliability, and performance for every product.

.jpg)

Definition: What Is Precision Machining?

What is precision machining is a frequently asked question in the industrial manufacturing sector. It is the process of using advanced machinery and technology to produce components with highly accurate dimensions and extremely small tolerances, often measured in micrometers. This process primarily uses CNC machines, which operate automatically based on programmed CAD/CAM data to ensure exceptional accuracy and repeatability.

To explain what precision machining is in simpler terms: it is the process of removing material from a workpiece according to programmed tool paths to create products that meet strict technical standards required in industries such as aerospace, medical equipment, automotive engineering, robotics, and electronics.

Why Is Precision Important in Manufacturing?

.jpg)

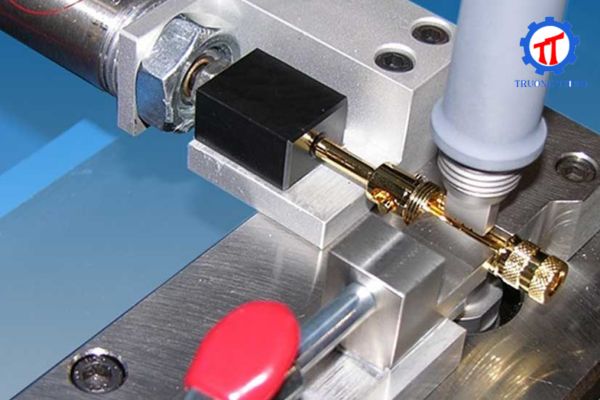

Before learning more about what precision machining is, it is important to understand why accuracy is crucial in technical products. Accuracy not only affects product quality but also impacts safety, durability, and operational efficiency.

Enhances Quality and Reliability

Precision machining ensures that all components meet exact specifications, resulting in high stability and consistency. This is especially critical in the medical field, where even a single millimeter on a surgical tool can affect patient safety.

Perfect Fit and Reduced Assembly Errors

Components produced through precision machining minimize dimensional deviations, ensuring perfect alignment during assembly. This helps save time, reduce rework, and improve overall durability.

Ensures Safety in Harsh Environments

In industries like automotive or aerospace, even the smallest error can cause severe incidents. Precision machining ensures components operate reliably under high pressure, high speeds, and extreme temperatures.

Long-Term Cost Efficiency

Although the initial investment in equipment is high, precision machining reduces waste, optimizes material usage, and increases productivity—resulting in long-term savings.

Supports Technological Innovation

With the ability to produce complex components, precision machining plays a critical role in developing new technologies, especially in robotics, microchips, renewable energy, and smart devices.

Reference: http://cokhiphutrotruongthinh.com/ky-thuat-phun-son-tinh-dien-la-gi-quy-trinh-chuan-xac-nhat-bv.html

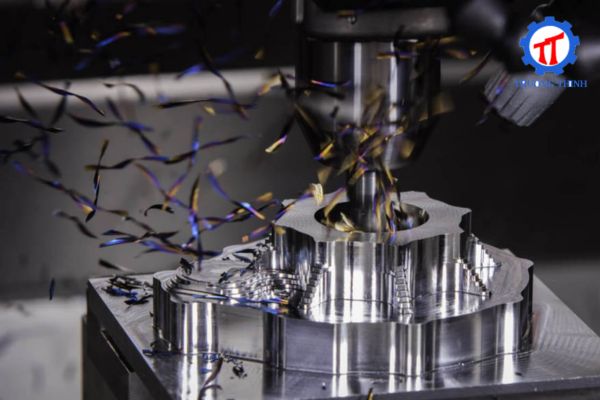

Capabilities of Precision Machining

.jpg)

This technology offers capabilities that traditional manufacturing methods cannot achieve.

High Accuracy and Extremely Tight Tolerance

CNC precision machining typically achieves tolerances up to ±0.001 mm, meeting the highest technical requirements of specialized industries.

Complex Geometries

Multi-axis CNC machines can produce parts with complicated shapes, small grooves, deep holes, and curved surfaces.

Wide Range of Materials

Materials include aluminum, steel, titanium, engineering plastics, and composite materials—all machinable with high precision.

Multi-Axis Machining (3–5 Axis)

This reduces the number of setups, increases accuracy, and shortens machining time.

Excellent Surface Finishing

Many components require no polishing or post-processing as the machined surface already meets finishing standards.

Suitable for Prototyping and Mass Production

Precision machining is ideal for both prototype development and large-scale manufacturing.

The Precision Machining Process

The process follows strict steps to ensure accuracy and quality.

-

CAD Design and CAM Programming: Engineers create digital technical drawings and program tool paths using CAM software.

-

Selecting Suitable Materials: Materials are chosen based on strength, weight, heat resistance, and application requirements.

-

CNC Setup and Calibration: This is a crucial step to ensure machining accuracy.

-

Roughing and Finishing: The machine performs milling, turning, drilling, and grinding according to the programmed operations.

-

Cooling and Chip Removal: Coolant helps reduce heat, extend tool life, and improve surface finish.

-

Inspection and Quality Control: Tools such as electronic calipers, CMM machines, and profile measurement instruments are used to guarantee tolerances.

-

Surface Finishing Treatments: Processes may include anodizing, anti-corrosion coating, galvanizing, or polishing.

Conclusion

What is precision machining is not only a technical concept but also the foundation of all modern industries. This technology delivers exceptional stability, durability, and safety in every product. With the ability to manufacture intricate and highly accurate components, precision machining is the optimal solution for businesses aiming to enhance product quality and production capacity.

Trường Thịnh Mechanical Information

Hotline:

Mr. Hưng: 0936.988.978

Mrs. Tâm: 0904.488.455 – 0225.627.79.97

Factory Address: Area C, No. 57 km5, Lam San, So Dau Ward, Hong Bang District, Hai Phong

Website: http://cokhiphutrotruongthinh.com