Reliable and High-Quality Custom Mechanical Processing Company

A custom mechanical processing company is becoming the top choice for businesses thanks to its ability to create accurate, flexible, and cost-optimized products. At Truong Thinh Mechanical, all technical requirements are handled using modern technology, a highly skilled team, and a strict quality control process. This article helps you understand why custom machining services are increasingly essential in today’s manufacturing industry.

.png)

The Need for Custom Mechanical Processing in Today’s Production

In a highly competitive market, businesses require mechanical components with high precision, suitable for various applications, and optimized production time. A custom mechanical processing company is the unit that helps enterprises meet these demands.

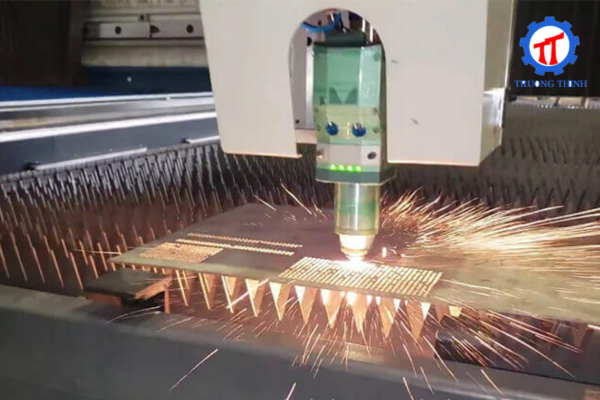

By applying CNC machines, automatic turning–milling systems, laser machines, and experienced technicians, custom processing services create consistent components, reduce errors, and enhance product durability.

Benefits of Working with a Custom Mechanical Processing Company

.png)

Before choosing a provider, businesses should understand the real advantages the service brings.

Optimized Production Costs and Time

A custom mechanical processing company helps businesses avoid investing in expensive machinery or training operators. This shortens production time and significantly reduces costs.

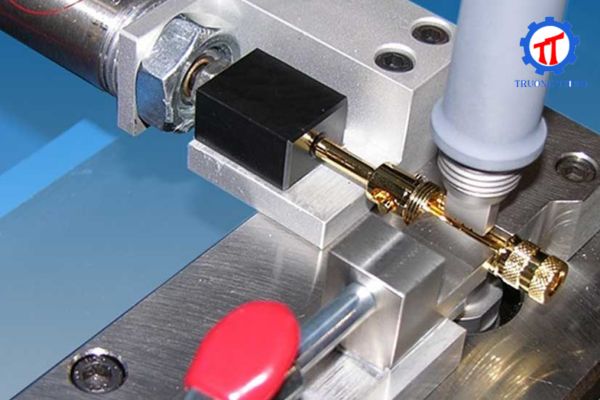

High Precision and Durability

With modern CNC technology and 3D measurement systems, components achieve high accuracy, suitable for industries requiring strict tolerances such as precision engineering, electronics, molds, and supporting industries.

Flexible for All Quantities

Whether producing prototypes, small batches, or mass manufacturing, a custom mechanical processing company always provides suitable and cost-effective solutions for each order.

Working Process at Truong Thinh Mechanical

To ensure efficiency and minimize risks, Truong Thinh applies a professional, clear, and consistent workflow.

Receiving Drawings and Technical Requirements

Customers provide 2D, 3D drawings or product descriptions. The engineering team will advise on materials, machining methods, and cost estimates.

Machining Plan and Technology Selection

Truong Thinh’s custom mechanical processing company uses a wide range of modern equipment: CNC lathes, 3–4 axis CNC milling machines, metal laser cutters, surface grinders, and automatic drilling–tapping systems.

Machining, Assembly, and Quality Inspection

Products are manufactured according to the approved plan and inspected with standardized measuring equipment to ensure the lowest error rate.

Delivery and After-Sales Support

Truong Thinh provides warranty support and assists customers with design adjustments or performance optimization when needed.

Why Choose Truong Thinh Mechanical?

As a reputable custom mechanical processing company with many years of experience, Truong Thinh owns numerous advantages that make businesses feel confident when cooperating.

Experience Across Multiple Industries

Truong Thinh has manufactured thousands of components for the electronics, automotive, machinery, precision engineering, and industrial manufacturing sectors.

Modern Machinery System

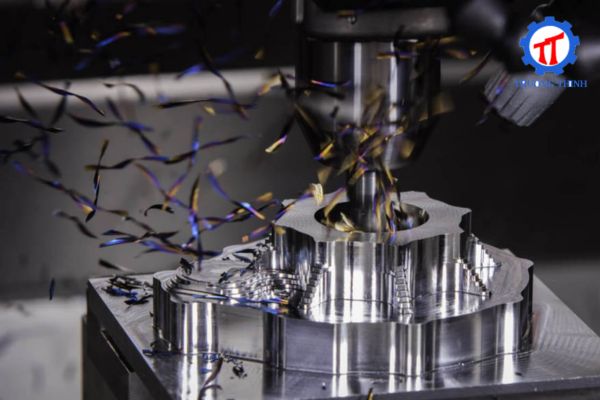

All production stages are automated, ensuring fast machining speed and excellent surface finishing quality.

Highly Skilled Engineers

Truong Thinh’s engineers are well-trained, capable of reading complex drawings, handling technical challenges, and offering optimal solutions.

Transparent and Flexible Pricing

The company always provides itemized quotations based on materials, machining methods, and order quantity, helping customers easily control costs.

Outstanding Machining Services at Truong Thinh

.png)

Below are the most popular services chosen by many businesses:

CNC Mechanical Parts Machining

Includes milling – turning – drilling – tapping stainless steel, steel, aluminum, copper, and engineering alloys with high precision and minimal errors.

Metal Laser Cutting and Engraving

Used for producing nameplates, industrial components, decorative accessories, and mass-production parts.

Design and Manufacturing on Demand

A custom mechanical processing company can quickly create prototypes, manufacture products based on drawings, or restore used components.

Conclusion

Truong Thinh Custom Mechanical Processing Company is a trusted partner for businesses seeking high-quality, precise, and cost-optimized products. With modern technology, a professional engineering team, and strict quality control, Truong Thinh ensures competitive pricing, fast turnaround, and stable quality. Choosing our machining services helps your business enhance productivity and achieve sustainable growth.

Contact Information – Truong Thinh Mechanical

Hotline:

Mr. Hung: 0936.988.978 - Mrs. Tam: 0904.488.455 - 0225.627.79.97

Factory Address: Zone C, No. 57 km5, Lam San, So Dau Ward, Hong Bang District, Hai Phong

Website: http://cokhiphutrotruongthinh.com